Service

Risk-based Process Safety Management

Consulting Service

CoreSafety® becomes the core of Risk-Based Process Safety Management System by visualising the plant's risk profile.CoreSafety® also enables the sharing risk profile within an organisation to optimise asset management programme.

Though, there are several types of hazard register format exist in the plant industry, JGC has developed CoreSafety®, based on the Fault Schedule, that has been used in the nuclear industry in the UK. CoreSafety® is risk management software that visualises process risks and supports Risk-Based Process Safety Management by providing risk profile information of the facilities and key functional requirements, which allows optimisation of asset integrity management programme.

CoreSafety® has a library function for easy set-up and an intuitive user interface. Risk profile is updated by entering the asset integrity management statistics (i.e, site specific failure rate data), so that the Risk-Based Process Safety management performance can be shared within the organisation.

CoreSafety® is a web application that can be used via internet browser. You can view risk management information from any location with your registered ID and password. CoreSafety® service is certified by both ISO 27001/ISO27017, the international standards for information security management and cloud service security.

Four Values

-

Visualise Risk Profile

Risk is visualised using digitalised "Fault Schedule", one of the hazard register formats, converted from the risk assessment information.

-

Easy Set Up via Library Data

The Fault Schedule can be easily set up by using the library, which summarises the JGC Group's extensive risk assessment experience.

-

Easy Access via Web Browser

Digitalised "Fault Schedule" on the cloud can be accessed by any member within the organisation at any time and from anywhere via web browser.

-

Centralise the Functional Requirement Management

CoreSafety® centralises the functional requirements for safety critical elements and performance monitoring of Risk-Based Process Safety Management System by KPI within the organisation.

Key Features

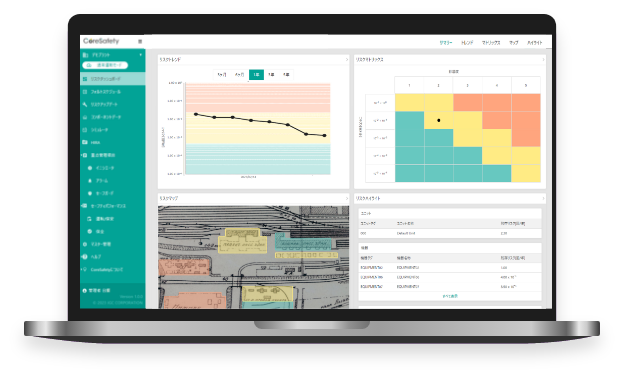

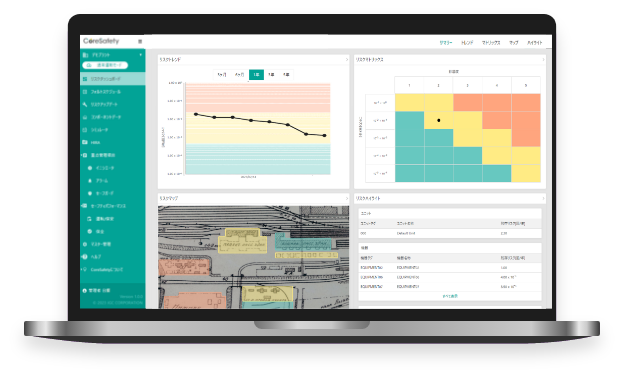

Risk Dashboard

Visualises dynamic risk trend as a results of Risk-Based Process Safety management performance and residual risks on a risk matrix and a plot plan.

Risk dashboard can be shared and reported within the organisation.

Update to Site-Specific Risk using Operational Records

Can be updated by Bayesian with site specific operational records (i.e, failure rate)

Risk can be referred as an key performance indicator to measure the effectiveness of Risk-Based Process Safety management.

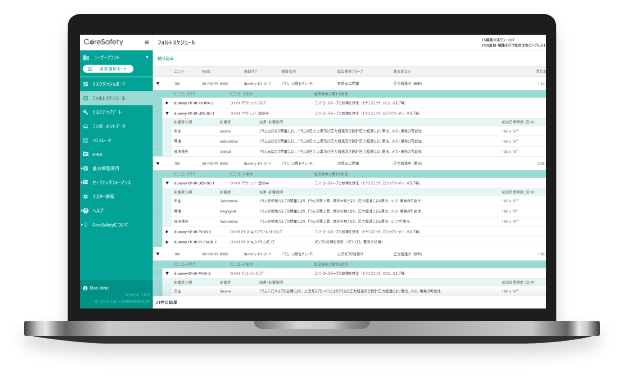

Digitalised Fault Schedule

The digitalised fault schedule in the cloud server allows all members in organisation to easily access to up-to-date risk profile and functional requirements for operation and maintenance tasks.

Appropriate asset integrity management requirements (e.g. frequency of start-up tests) can be assigned from the process safety risk perspective as the core information of Risk-Based Process Safety management.

How It Works

-

1

Launching CoreSafety® Server

Please submit registration form and confirm initial data set-up sheet prior to server set-up.

-

2

Build Fault Schedule using Fault Schedule Library Function

Fault schedule database can be set up by using Fault Schedule Library, pre-set Fault Schedule per Equipment Type (constructed from JGC Group's extensive risk assessment experience).

-

3

Start Risk Based Process Safety Management using CoreSafety®

CoreSafety® enables to optimize Operation & Maintenance management by prioritising safety critical elements and alarms.

CoreSafety® also enables to visualise safety performance within the organisation by setting KPI. -

4

Update Risk using Site-Specific Operational Records

The risk can be regularly updated by site specific operational records (i.e, failure rate), which helps continuous improvement on Risk Based Process Safety Management Program.

Subscription Plans

CoreSafety® service fee is an Annual Subscription.

Contact Us for more Information.

CoreSafety® Consulting Service

Plant facility design data and its risk profile form the foundation of PSM (process safety management), that define appropriate functional requirements for safety critical elements or tasks. Risk assessment methods such as HAZOP and LOPA are often used to define the risk profile. The quality of risk assessments are, thus, very critical.

CoreSafety® consulting service provides supports establishing RBPS, coaching of risk assessments, and training program to together with CoreSafety.

PSM (Process Safety Management) consulting provides consulting service to convert PSM system to a risk-based. The introduction of the Risk-Based Process Safety rationalises the management of high hazardous/high risk facilities/tasks by prioritizing from process safety risk perspective.

JGC can also supports you integrating the management systems (PSM with quality, environmental and occupational safety management systems).

We provide service developing skills required to implement HIRA (Hazard Identification and Risk Assessment), e.g, preparing procedures, coaching facilitators in workshop.

We can also support preparing various forms of hazard registers. If you use the CoreSafety® as the digitalised hazard register, it must enhance effective use of risk assessments' result in RBPS management system.

The most important aspect of the conduct of PSM is the competency management of staffs within the organisation. We provide the necessary training programmes (e.g, PSM, HIRA, process safety techniques) for those whose positions require to carry out PSM related tasks. Competency assessments can also be carried out in conjunction with the programme.